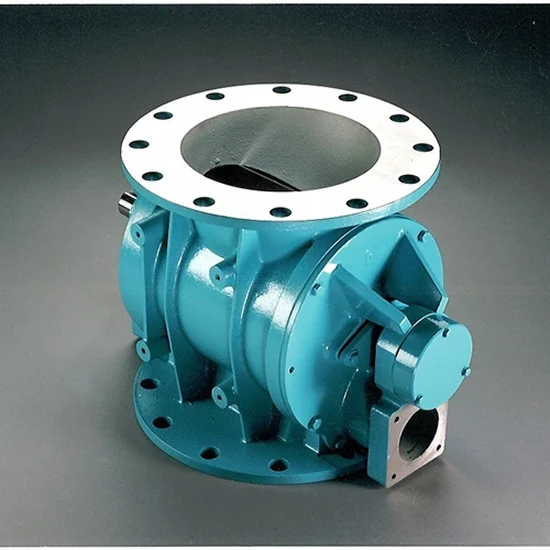

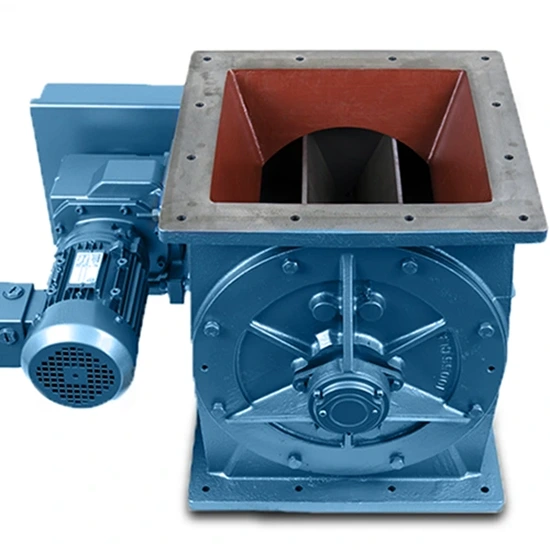

In dust collection systems, dust particles and suspended materials are collected by filters or other equipment. These collected materials must be regularly removed from the system to prevent accumulation and maintain system efficiency. This is where the rotary valve comes into play. The collected materials enter the rotary valve chamber. The rotating rotor (rotating blades) directs these materials from the chamber toward the discharge point. In this process, the rotary valve prevents air from entering the dust collection system and avoids re-dispersion of dust particles. The discharged materials can be directly transferred to storage tanks or material handling systems.

How Rotary Valves Work

Rotary valves are industrial valves that precisely control the flow of liquids and gases. These valves consist of a body and a rotating disc that regulates the flow by turning. They are used in industries such as oil and gas, chemical, food, and water/wastewater. Their advantages include high precision, reduced pressure drop, and compact size. Rotary valves ensure optimal performance in industrial systems by accurately adjusting pressure and temperature, and they can also be used in confined spaces. These valves are designed for precise flow control and regulating the amount and direction of flow.

Advantages of Rotary Valves

Rotary valves, particularly the Zist Filter brand, offer numerous benefits in various industries due to their unique features:

High Reliability: Rotary valves have a simple and robust structure, ensuring high reliability with minimal maintenance requirements. This reduces upkeep costs and extends the device’s lifespan.

Precise Flow Control: These valves can accurately control material flow and adjust discharge rates from tanks or silos. This feature is crucial in industries requiring high precision in material quantities.

Preventing Air Ingress: In some systems, rotary valves prevent air from entering the system, maintaining pressure or specific conditions. This enhances system performance and avoids potential issues.

Continuous or Periodic Discharge: Rotary valves can discharge collected materials continuously or periodically, improving system efficiency. This is especially important in dust collection systems requiring regular material discharge.

Zist Filter Company’s Rotary Valves

Zist Filter proudly announces its expertise in manufacturing and developing rotary valves. Leveraging cutting-edge technical knowledge and years of industry experience, the company produces high-quality rotary valves with optimal performance. Zist Filter’s rotary valves are used in various industries, including food, chemical, plastics, and more. They are suitable for bulk material transfer, air ingress prevention, and flow control.

بدون دیدگاه