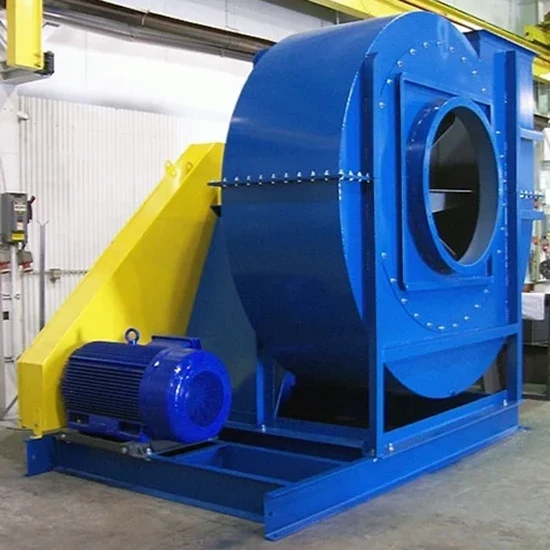

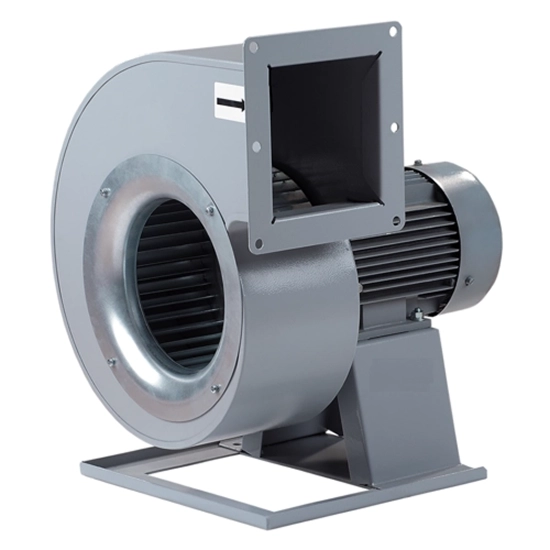

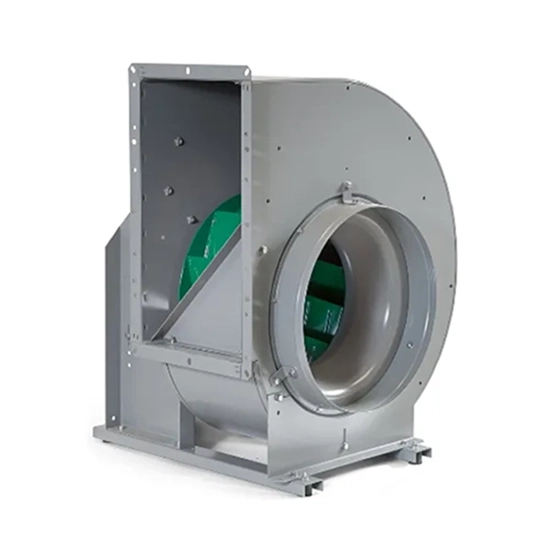

Centrifugal Fan , also known as radial fan or blower, is one of the most widely used equipment in the HVAC industry. This device uses centrifugal force to move air or gases and is used in various industries including building ventilation systems, vehicles, and air pollution control systems.

Compared to other fans, centrifugal fans produce higher air pressure but have lower air output volume. Due to their simple design and low production cost, these fans are very popular in industry. Centrifugal fans, the most widely used type of fan in industry, are used for ventilation and air pollution control due to their reasonable price and high efficiency. Zist Filter Company offers these fans with superior quality.

These fans, also known as blowers, are also used in transportation industries and building ventilation systems and vehicles.

How Centrifugal Fans Work

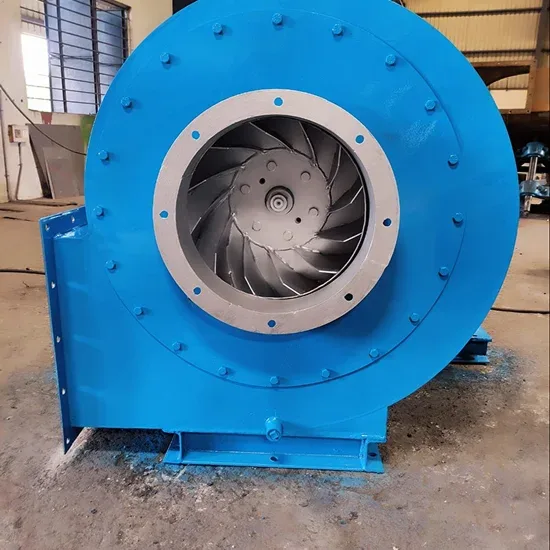

A centrifugal fan, also called a radial fan, consists of an impeller with multiple blades housed within a cylindrical casing. As air enters the fan and the impeller rotates, it is subjected to centrifugal force and directed toward the fan outlet. The air entry and exit angles in this fan are 90 degrees, meaning air enters and exits perpendicular to the impeller axis. In centrifugal fans, air moves from the impeller toward the blades, increasing its kinetic energy. This kinetic energy is converted to pressure energy upon exiting the fan, creating high pressure. Zist Filter manufactures centrifugal fans in various sizes.

Advantages of Centrifugal Fans

Centrifugal fans have become one of the most widely used equipment in various industries due to their numerous advantages. Below are some of these advantages, both general and specialized:

Stable Airflow Generation: Centrifugal fans produce a more consistent and steady airflow, which is essential for many industrial and HVAC applications.

Ability to Overcome Static Pressure Loss: These fans can overcome static pressure loss and effectively exhaust air even at low static pressures, contributing to proper ventilation.

Reduced Production Costs: The simple design of centrifugal fans allows for quick and easy manufacturing, lowering production costs.

Suitability for Harsh Conditions: These fans can operate in environments with high temperatures and pollution.