Products

Zist Filter Company manufactures products such as centrifugal fans, dust collectors, filter bags, cages, rotary valves, and screw conveyors. These advanced technology equipment separate suspended particles and dust from the air and are used in industries such as steel, cement, and chemicals. Zist Filter’s goal is to reduce air pollution and improve environmental quality.

Centrifugal Fan

Centrifugal fans, also known as radial fans, are a type of ventilation system that uses centrifugal force to move air or gases perpendicular to the axis of the impeller's rotation. With their unique design, these fans generate high air pressure and are used for transferring and separating airborne particles in various industries such as cement, steel, chemical, and food processing. Due to their robust construction, high efficiency, and ability to operate in high-temperature and polluted environments, centrifugal fans are an ideal choice for ventilation and air pollution control systems. Key advantages of these fans include long durability, easy maintenance, and versatility in diverse applications.

Dust Collector

A dust collector or bag filter is an industrial filtration system used to capture airborne particles and pollutants in work environments. This system consists of fabric filter bags that trap dust particles while returning clean air to the environment. Dust collectors are widely used in various industries such as cement, steel, pharmaceuticals, and food processing. Their operation involves contaminated air entering the dust collector chamber, where dust particles are collected on the surface of the filter bags, and clean air is then discharged from the system. Cleaning methods such as shaking, reverse airflow, or pulse jet are used to clean the bags.

Bag Filter

Bag filter or baghouse filter is an air filtration system widely used in various industries, particularly in metal smelting furnaces, to capture suspended particles and dust. These systems use fabric filter bags to separate dust particles from the air stream and return clean, hygienic air back into the environment. The operation of bag filters involves drawing in contaminated air, passing it through the filter bags, and collecting particles on the surface of the bags. The filtered air is then released from the system, while the collected particles remain trapped in the bags. To enhance the efficiency of the bags, techniques such as reverse air cleaning and pulse-jet cleaning are utilized.

Bag Filter Cage

The bag filter cage, or filter bag cage, is made of carbon steel or stainless steel and is reinforced with coatings such as galvanization. This component consists of vertical and horizontal wires and is produced in round or flat shapes. The bag filter cage acts as a support for the filter bags, maintaining their shape and enhancing filtration efficiency. This part is manufactured in various sizes and is made of stainless steel for humid or corrosive environments, playing a key role in extending the lifespan of filter bags and improving the performance of the dust collection system. The use of a venturi at the top of the cage facilitates the bag cleaning process. These features help optimize the efficiency of filtration systems and reduce energy consumption in industrial processes. As a result, the bag filter cage is recognized as an essential component in air pollution control equipment.

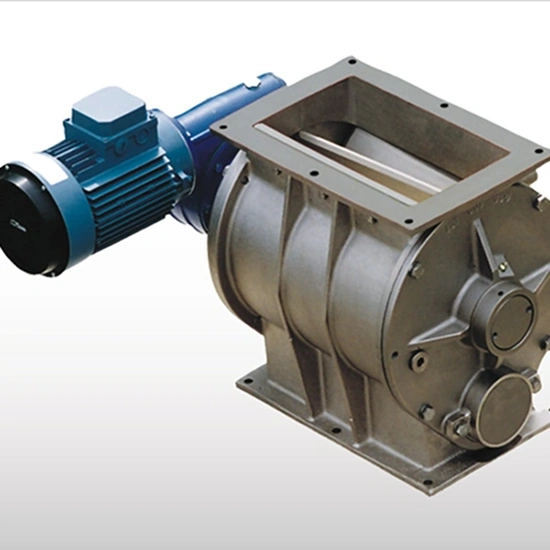

Rotary Valve

Rotary valves (rotary airlock valves) are a type of pneumatic valve used to control and transfer granular or powdered materials in various industries. These valves use a rotating rotor to transfer materials from the inlet to the outlet while regulating the flow. Rotary valves consist of four main and essential components: the outer housing, rotor, bearings, and drive. There are different types of rotary valves based on housing design, rotor type, and drive mechanism, which are used for various applications such as pneumatic conveying, precise material dosing, and process isolation. Selecting the appropriate rotary valve depends on factors such as material type, operating speed, temperature, and pressure. These valves play a key role in preventing material loss and maintaining system pressure. Additionally, the use of rotary valves significantly enhances productivity and reduces production line downtime.

Screw Conveyor

Screw conveyor or auger conveyor is a material handling system used for transporting bulk materials such as powders and granules in various industries. This system consists of a shaft with helical blades that, through rotation, move materials forward or backward. Screw conveyors are widely used in food, chemical, and pharmaceutical industries. The main components include the screw, drive motor, and supporting frame. Its advantages include low maintenance costs and design flexibility, though it is not suitable for long-distance transport. Due to their adjustable speed capability, these systems are considered an ideal choice for industrial production lines. Additionally, screw conveyors can be designed in horizontal, vertical, or inclined configurations and are suitable for use in confined spaces. The use of these systems enhances productivity and material handling safety.