Zist Filter Co.

The first designer and manufacturer of industrial dust collectors in Iran

Reducing costs and increasing productivity

Reducing costs and increasing productivity by optimizing performance and reducing energy consumption

International standards

By complying with the relevant standards, "Zist Filter" provides customers with trust and reliability in their devices

Experience and technical strength

More than several decades of experience in designing and manufacturing industrial dust collection devices

Our Products

"Zist Filter" Company is a manufacturer of dust collection devices and related accessories. Our products include:

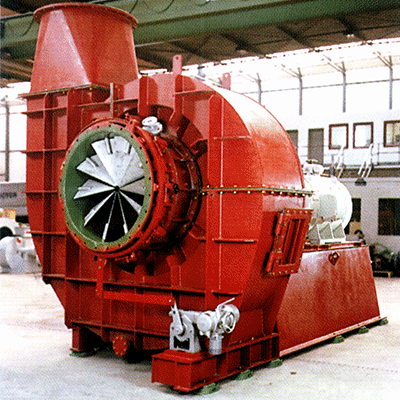

Centrifugal Fan

Centrifugal fan is a high-powered device produced by “Zist Filter” Company and used to transfer and separate airborne particles and dust materials. The centrifugal fan has advanced technology and optimal design that provides high suction power and aeration. By using a shaft and curved blades, the centrifugal fan creates a strong air flow that separates suspended particles from the air and acts as an effective solution in reducing air pollution. Centrifuge fan is also commonly used in various industries such as steel, cement, chemical and food. In addition to high power and efficiency, the “Zist Filter” centrifugal fan with silent and low-noise design helps to improve the performance of dust collection devices and provides reliability and reliability for customers.

Dust Collector

“Zist Filter” Company designs and produces all kinds of dust collection systems according to the needs of different industries. These systems include multifunctional and customized devices based on the specific needs of customers. By using advanced technology and optimal energy consumption, “Zist Filter” dust collection systems make a significant improvement in the separation and collection of dust particles and pollutants suspended in the air. These systems help customers experience improved air quality in their work and living environments, especially in industries that face the production of dust particles and high-potential pollutants. “Zist FIlter” dust collector systems can completely trap fine and suspended particles in the environment and prevent them from entering the clean air, and also have the ability to use various filters to meet the specific needs of customers.

Filter Bag

The filter bags produced by “Zist Filter” are made of superior quality materials and are used to absorb and separate suspended particles and various pollutants in the air using advanced technology, including nanofiber technology. “Zist FIlter” filter bags with strong design and proper structure, have high performance and long life. These bags act as an essential part of dust collection systems and improve the ability to collect and hold suspended particles. Through the easy passage of air through the filter bag, dust particles and pollutants are effectively absorbed and separated and protected from entering the environment. Also, these bags have properties such as resistance to corrosion and high temperature, ability to wash and recycle, and high efficiency in separating small particles.

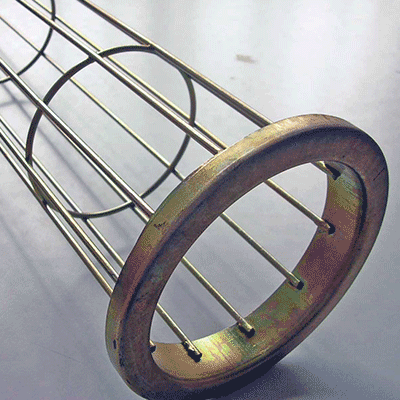

Cage

The cage is an important part of the dust collection devices produced by the “Zist Filter” company. This basket is used to store and support filter bags in dust collectors. The metal baskets produced by “Zist Filter” are made of durable and quality materials to give the filter bags the necessary strength and stability. These baskets, with proper design and coordination with dust collection systems, use safe and simple connection methods for bags. They act as the support and builder of the internal structure of the bags and help the correct and optimal functioning of the dust collection system. “Zist Filter” baskets also have features such as impact resistance, pressure resistance, and high durability.

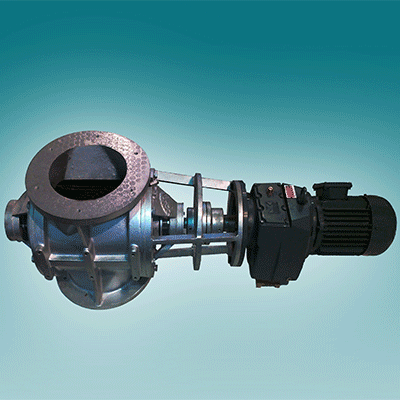

Rotary Valve

Rotary Valve is an essential part of dust collection devices produced by “Zist Filter” Company. This valve acts as an automatic gate and helps to drain and collect dust particles and suspended materials from the dust collection system. The “Zist Filter” rotary valve provides reliable operation without the need to stop the system with a strong and resistant design. This valve opens a path for dust particles to exit the dust collection system with the rotary movement of the vanes, and while maintaining the appropriate air pressure, it prevents the re-release of particles into the environment. “Zist Filter” rotary valve helps to improve the efficiency and performance of the system with its ability to be installed and compatible with different dust collection systems.

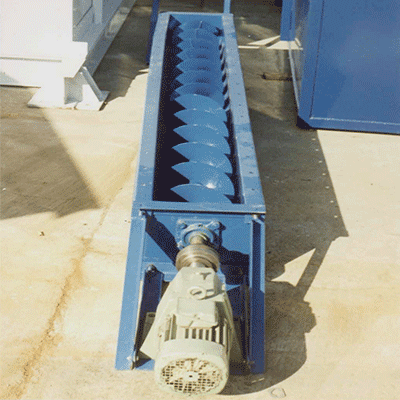

Screw Conveyor

Screw Conveyor is one of the important equipments in dust collection devices produced by “Zist Filter” Company. This equipment is used to collect and transport dust particles and suspended materials separated from the dust collection system. Screw Conveyor “Zist Filter” with a solid and stable structure offers high strength and efficiency in moving dusty materials. Using a rotating screw, the screw conveyor continuously transports dust particles from the dust collection device to the collection tanks or subsequent devices. In addition to the ability to carry and move dusty materials, this equipment has features such as resistance to wear, the ability to adjust the speed and volume of movement, and a long life.

FAQs

Zist Filter’s filter bags are used in many industries, including cement industries, steel and foundry industries, chemical industries, food industries and mining industries. These bags are used to separate and purify dust particles and airborne particles.

Centrifuge fans of “Zist FIlter” company are used to collect and discharge airborne particles and industrial dust. These devices are used in industries such as cement industries, refineries, steel factories, chemical industries and food industries.

Yes, in addition to the production of its products, “Zist Filter” also provides after-sales services. The company’s technical and customer service team is ready to respond to customers’ questions and needs, and will provide the necessary cooperation and coordination in case of installation, setup and more technical services.

Satisfied Customers